Posted to News on 6th Mar 2025, 12:05

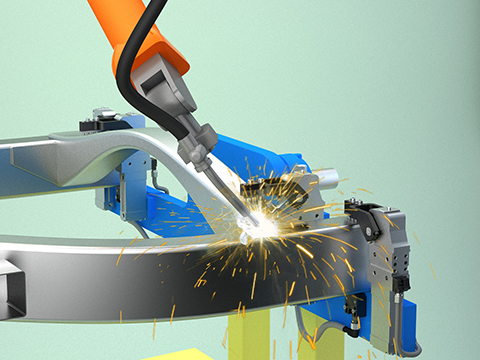

Weld spatter-resistant weld-immune sensors and accessories

Contrinex's Weld-immune sensors have had an exceptional reputation for performance for a long time, but Contrinex has continued to develop and expand its offering for welding applications.

The company's weld-spatter resistant sensors and accessories are specifically designed to enhance efficiency and quality control in challenging welding environments. These advanced solutions ensure precise part positioning while significantly reducing defects and equipment damage.

A typical application is their use to ensure components are accurately positioned. By eliminating misalignments and undetected faulty assemblies, manufacturers can drastically reduce costly downstream scrap and rework.

Contrinex's ACTIVSTONE ceramic coating option extends the sensor's lifespan and minimises maintenance requirements in areas exposed to weld-spatter, leading to lower operational costs.

The spatter-resistant weld-immune sensors and accessories enable Contrinex's sensor and accessory technology to be used in very challenging welding environments. Manufacturers can optimise their welding performance and seek greater precision, to enhance product quality, and maintain a competitive edge in the evolving automotive landscape.