Posted to News on 28th Jul 2017, 00:00

The many uses of wire forms

Springs are widely used in applications across the many engineering and manufacturing sectors. So we might think we know all there is to know about them. But, as the experts at European Springs point out, wire forms are too often forgotten or overlooked.

A wire form is a piece of spring metal wire that has a particularly unique design to it, where the design helps to aid a function. For example, a wire form could be created to hold an electronic pin in contact with the motherboard of a computer. The main advantage of wire forms is that they are incredibly versatile and are one of the most customisable items available in the spring manufacturing industry. Wire forms can come in a range of shapes, sizes, and materials, and they are used in an array of industries.

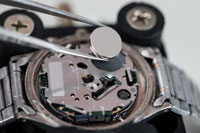

The most common use of wire forms is as metallic contacts in electronics. One application that everyone will be very familiar with is in battery holders. There are two components to the contacts in a battery holder; one has a spring and the other has a small metal clip. That small metal clip is a wire form, and it helps to ensure that the battery remains in the holder and in contact with the device.

Another use of wire forms in electronics is holding electrical wires in place. This is to ensure that each contact is connected to the correct terminals; a common example of this would be in wire clippings on various circuit parts. They are also common in light fixtures, as they ensure the light bulbs can be held into the fixture correctly without any issues. The wire form needs to be strong enough so that it can hold the light in place, meaning that extra measures need to be considered in the designing and manufacturing phases.

The goal for a design engineer is to work on products and systems that use various mathematical and scientific techniques to come to a complete solution. For example, if a client were to ask for a solution to a problem, a design engineer would think of the different possibilities of solving that problem, and then test every single one until a final solution was determined.

However, with technology advancing every day, more complex problems are coming to design engineers daily. Because of this, it can become increasingly difficult to provide an effective solution within a given timeframe, due to the complexity of the task in question.

This could potentially result in the design engineers facing a technological system or a component that they may not be familiar with, which can lead to them having to solve the design problems by other means. These issues could be that the system doesn’t have the correct functionality, it could be too expensive to implement, or the design of the solution could be too complex and time-consuming when replicating it on a larger scale.

The most important reason wire forms can be used to provide a solution to the issues is because they don’t have to take a constant shape. Wire forms are manufactured through a computer numeric control machine, or a CNC machine, which can take any design you wish to replicate and create.

This is popular in creating circuit boards to companies around the world, and it is also common in the spring manufacturing sector. This means that any design that you place into the CNC machine will be replicated as a final product. As such, wire forms can take any shape or size you wish.

With this, you can design a component and then use a CNC machine to create the wire form which can then be used within the final solution. This can greatly simplify the designs that are required during the problem-solving phase. Also, because this enables you to create multiple wire forms using easily adjustable designs, the costs are reduced, which can benefit your designs, as well as the company that they are working with.

These all work together to ensure that wire forms can be used to solve any problem that may come up within the engineering and manufacturing sectors. They can be as complex or as simple as you wish but, either way, they can provide the best solution for any issue, whether it is a misplaced contact or a component that is required to fit another component in place.

With technology developing constantly, there are some people who believe that wire forms will become obsolete in the near future but, since the advancement of wire forms comes from technological developments, it is safe to say that wire forms will maintain their role in helping engineers around the world achieve the correct and best solutions possible.

European Springs & Pressings Ltd

Lindley Moor Rd

Spring Moor

HD3 3SH

UNITED KINGDOM

01422 377335/370770