Posted to News on 1st Apr 2014, 00:00

Tablet counting systems rely on HepcoMotion ring and slide accuracy

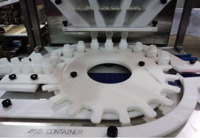

Pharma Packaging Systems, a specialist in the design and manufacture of electronic tablet/capsule counting machines, is deploying the latest PRT2 precision rings and GV3 linear slides from HepcoMotion for a new counting machine with tare gross weighing system. The HepcoMotion products were selected for their "accuracy and performance", factors well proven at Pharma Packaging - the company has been a HepcoMotion customer for over 10 years.

The demand for the new PC180 counting machine with tare gross weighing system arrived at Pharma Packaging via an application based on substitute narcotic tablets for a pharmaceutical customer in the USA.

"The system had to be quick, hence the configuration allows three containers to be filled with tablets [counted], weighed and checked simultaneously," explains Technical Director, Ian Barnes. "However, the overriding priority is accuracy as we are dealing with a very important pharmaceutical application. We have used HepcoMotion products since our inception. Their products are accurate and perform well - in 11 years we've not had a failure, so why change?"

The PC180 system indexes empty containers three at a time, weighs them and records the weight (tare). The containers are then indexed again and filled with a counted number of tablets. A final index sees the containers being weighed once more. Finally, the tare weight is subtracted from the product weight and the system identifies containers that either comply with the target weight, or fail. Good product advances to an out-feed conveyer, while failing product is diverted down a chute to a reject area.

The PRT2 precision ring system is based on HepcoMotion's V guide technology and features an integral rack and pinion drive, which facilitates the precise indexing mechanism thanks to its friction-free, zero-play motion.

"We've found HepcoMotion's PRT2 system with integral rack to be quite unique, at least we haven't seen it anywhere else," says Mr Barnes. "It's very easy to design around. In particular, it has allowed us to do away with the centre bearing mounting. This means we can run the conveyor through the centre - it doesn't need to be offset - thus enhancing accuracy - because containers that are not at 90° to the centreline can sometimes be a problem. We also like the fact that the PRT2 can run dry, without any need for lubrication, which is very important for pharmaceutical applications."

Elsewhere in the same machine, HepcoMotion's GV3 linear motion V guide and actuator systems are used for two different applications: in a vertical configuration to raise and lower the filling nozzles, thus accommodating different container sizes; and in a horizontal configuration to guide pneumatic cylinders which actuate gates that allow tablets through before closing-off for the next batch.

The PC180 counting machine is now complete and on its way to the end user. However, far from being a one-off, Pharma Packaging expects to sell more in the future and says special application machines are proving increasingly popular.

"A tablet counter is the heart of any solid dose packaging line and Pharma Packaging Systems operates with a focused approach so as to be the best in the industry at manufacturing this type of equipment. HepcoMotion is among the suppliers who help facilitate our ambition. Considering the accuracy on offer, their equipment provides a high quality yet cost effective solution," concludes Mr Barnes.

All Pharma Packaging Systems equipment complies with the latest cGMP requirements and is fully validated including 21CFR Part 11 compliance (where applicable). The systems are supplied with full documentation including detailed manuals, certification and IQ/OQ packages.

Formed in 2002, Pharma Packaging Systems has grown into a £2.5 million turnover, 14-employee organisation with customers around the world - exports account for 85% of sales. In the past two years the company has become ISO9001 accredited and has relocated into 15,000 sq ft premises at Pershore, Worcestershire.