Posted to News on 27th Jul 2015, 00:00

Shock absorbers key in new subsea connector design

Shock absorbers are playing an important role in a new design of emergency release connector for the offshore oil and gas industry, providing reliable disconnection in the event of a problem.

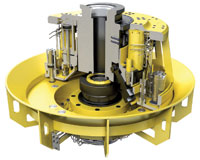

>Aberdeen based Subsea Technologies (STL) has developed a new family of emergency release connectors, the Xtreme Release (XR) Connector range, to remove the entire concept of 'maximum riser disconnect angle' - a long standing challenge of subsea riser design.

>The (XR) Connector differs fundamentally from all other subsea connectors because it is based on a face-to-face technology rather than a conventional male-into-female engagement. This key differentiator enables the XR Connector to release safely, reliably and repeatedly with up to 100% of maximum bending capacity applied.

>By comparison, existing connectors - even those that claim to be capable of 'high angle release' - cannot separate with high bending loads applied, so the maximum disconnect angle (and therefore the maximum applied bending load) has to be limited to prevent lock-up. Why is this important? Any floating vessel connected by a riser pipe to a wellhead on the seabed must be able to disconnect rapidly from the wellhead in the event of a position-keeping emergency.

>If it can't, there is a high risk of severe damage to the vessel (potentially causing injuries and fatalities), catastrophic failure of the riser pipe, severe damage to the wellhead and possibly loss of well containment. Existing emergency disconnect packages (EDPs) have to limit the maximum disconnect angle to prevent the EDP from 'locking up'.

>To maintain this small angle, the distance the vessel can move from the nominal centre position is limited and therefore the crew has only a small window of reaction time to identify a position-keeping failure, close in the well and disconnect from the wellhead. If the crew react too slowly, or problems occur too quickly for the crew to react, the vessel and its crew can rapidly reach the point beyond which the riser will not disconnect. Not a position any vessel crew, operator or owner would want to encounter.

>Because the XR Connector has no maximum disconnect angle and can release at up to 100% of maximum bending capacity, there is no risk of it locking up when released under load. This means that vessels can move much further away from the wellhead before disconnecting from the subsea wellhead, and when they do release, the vessel crew can be confident that there is no risk of finding the riser stuck.

>This unique capability means that the XR Connector offers greatly improved vessel safety, improved asset protection and improved productivity. The XR Connector also enables vessels to continue operations through more severe weather than previously possible, subject to other components in the riser system having sufficient bending capacity.

>Integral with the face-to-face seal technology are clamping dogs and, in a controlled or emergency release, significant kinetic energy can be imparted into the dogs. Subsea shock absorbers from Ace Controls International were designed into the assembly to safely absorb this kinetic energy and thus ensure that no damage occurs to the dogs or other equipment during the release.

>Ten Ace MC6450EUM-28449 Magnum stainless steel subsea shock absorbers used in every STL XR Connector. The shock absorber body is fitted into a purpose-made stainless steel side load adaptor and the black clamping dog which rises during the release is situated below it.