Posted to News on 25th Apr 2025, 15:00

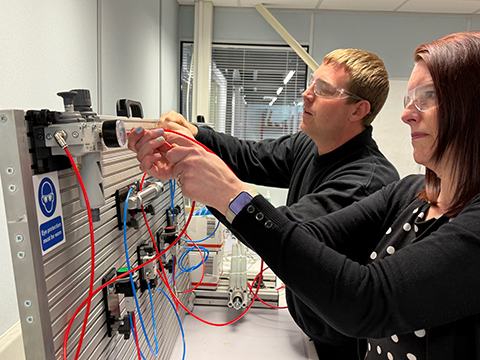

Reduce downtime with hands-on pneumatics training

Camozzi Automation is proud to offer a comprehensive "Introduction to Pneumatics" course, designed specifically for end users in industries where reliability and minimal downtime are critical.

This two-day course is particularly relevant for professionals in quarrying, tarmac, aggregates, and brick manufacturing - sectors often operating in harsh, dusty conditions where pneumatic system failures can be frequent and costly.

Pneumatic systems are the lifeblood of many industrial operations, yet even the most robust setups are susceptible to faults. Our course is structured to empower your team with the tools and knowledge needed to prevent these failures and keep operations running smoothly.

The courses are run by Steve Partington who has over 45 years' experience in the pneumatics industry. Steve has had many roles during his career including R&D, Applications Engineer and Technical Director. He says: "It is very satisfying to be able to pass on some of the knowledge and experience I have gained through a long and varied career to benefit the students on Camozzi's training courses." Key benefits include:

Reduce Downtime: Learn how to identify, prevent, and resolve common failures in pneumatic systems.

Experience Behind the Scenes at Camozzi: Tour Camozzi's facilities at The Fluid Power Centre, Nuneaton, and explore how the company supports industry leaders.

Delivered by Experts: With over 45 years of experience, Camozzi's training is led by Steve Partington - respected in the pneumatics industry whose background spans R&D, applications engineering, and technical leadership.

The blend of classroom theory and hands-on practical exercises ensures that learning is engaging, relevant, and immediately applicable. Held at Camozzi Automation's UK Headquarters in Nuneaton, the "Introduction to Pneumatics" course covers:

Training Outcomes:

1. Understanding compressed air system measurements

2. Recognising pneumatic symbols to ISO 1219 standards

3. Mastering the function of cylinders and valves

4. Building and reading circuit diagrams

5. Emphasising safe working practices

Course Content Highlights:

1. Compressed air production and treatment

2. Pneumatic actuators and valve technologies

3. Directional & flow control valves

4. Circuit design, construction, and troubleshooting

5. Practical exercises and application-based learning

Courses run throughout the year, with the first starting on 17 June. Cost is 499.99 per person, although discounts are available for multiple delegates.

The Fluid Power Centre

Watling Street

CV11 6BQ

UNITED KINGDOM

+44 (0)24 7637 4114