Posted to News on 23rd Jan 2017, 00:00

Polymer bearings in the groove of the vinyl revival

The vinyl revival of recent years has opened up an interesting new market for Igus, with the company now supplying plastic bearings to Rega for use in the company’s RB220 tonearms, used with the P1 and P2 turntables. One of the lowest friction and highest accuracy bearings that Igus has ever manufactured has helped Rega reduce costs, improve quality, expand its product range and reap the benefits of a more secure source of supply.

Turntable development is a field of design that is as much about art as it is engineering. Leading manufacturers of course approach it as an engineering challenge, but at the extreme when you’re judging the end result, it becomes a philosophy with different opinions.

This is the ethos that defines turntable design for Roy Gandy, whose company Rega has grown to become one of the leading lights in British hi-fi equipment. Founded in 1973, the company built its reputation on the quality of its turntables, and expanded its portfolio over the years to include tonearms, cartridges, loudspeakers, amplifiers and CD players.

Today, with more than 90 employees, Rega assembles over 40 different products at its purpose-built 30,000 square foot manufacturing and warehouse facility in Essex. And where once, along with most of the industry pundits, it thought it would see the death of vinyl, today the company is riding the wave of a vinyl revival, producing thousands of turntables every month. In 2015, as the UK’s largest manufacturer and exporter of quality, high precision record decks, Rega’s success was recognised with the Queen’s Award for Enterprise in International Trade.

One of the keys to the success of the company’s record decks is its innovative approach to tackling the engineering compromises of turntable design, with a philosophy and a use of materials that sets it apart from other manufacturers. “All engineering is compromise,” says Gandy. “The key to success is how you deal with those compromises.”

And while acknowledging that different users will like or dislike different products from different manufacturers, in the end Gandy is adamant that quality is never subjective.

The fine balance of engineering and art that leads to a successful turntable design also extends to the development of the tonearm. Rega has long been making its own range of tonearms, with the bearing being a critical component. On its lower end tonearms, Rega had been using imported bearings from the Far East, compensating for any tolerance on the diameter with increased compression to take out the play.

“Bearing tolerance has to be very tight,” explains Gandy. “The bearing has to allow free movement of the arm, but at the same time, if there is any play, it impacts on how the cartridge measures the movement of the stylus in the grooves of the record. When you assemble the tonearm, pressing in the bearing, you can feel if the tolerance is even half a micron out.”

With lead times on the bearings from the Far East increasingly variable, and shipping costs rising, Gandy was keen to find an alternative source of bearings. Also, as ball bearings require regular lubrication, there were potential maintenance concerns over time, as well as the possibility of the ingress of contaminants, such as dust. With this in mind, four years ago Rega engineers approached Igus at the Southern Manufacturing exhibition. “I didn’t believe they’d be able to make a plastic bearing with sufficient accuracy,” he says. “That was our key criterion; we didn’t need high speed, but we did need high accuracy.”

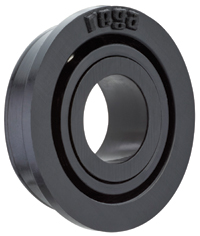

Seeing synergies with the Rega business, and spurred on by the potential afforded by the vinyl revival, Igus took up the challenge. After 18 months’ careful development, prototyping and testing, the team successfully produced a bespoke xiros bearing that met the stringent requirements and expectations Rega had for producing a perfectly balanced, absolutely friction-free tonearm, with no drag.

“The plastic bearing doesn’t actually have quite the accuracy of the original bearings, but with plastic there is much more scope for compression,” says Gandy. “Indeed, there is almost ten times the amount of tolerance in the fit. It’s also easier and faster to assemble into the tonearm, so there are lots of advantages.”

In many other areas, the xiros bearings compare favourably with the original metal ball bearings, particularly in terms of noise, vibration and acoustics, as well as delivering improved precision and better lead times. Gandy also comments that some people have said, subjectively, that the tonearms sound better.

The xiros bearings are currently used in Rega’s top two selling turntables, the P1 and P2, and are also now being evaluated for use in other tonearms and turntables in the range. “Our turntables and tonearms have to be more accurate than the equipment used to press vinyl,” concludes Gandy. “We think of the turntable not only as a means of playback, but as a precision measuring device that has to track and interpret the groove in each piece of vinyl it reads. The xiros bearings are critical in helping us achieve this ambition and we have enjoyed working hand-in-hand with the talented Igus engineers to make this happen.”