Posted to News on 2nd Jan 2006, 00:00

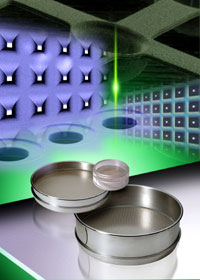

PEF sieves ensure 100% of material is accounted for

Technology has been developed which ensures fine particulate materials can be 100% accounted for during sieving processes, by Weymouth based ultra-fine metal mesh specialist, Tecan. The company's sieves and meshes do not use traditional woven-wire construction and therefore ensure that no sieved materials are trapped during sieving, filtering or grading processes - ensuring no-waste fine material control and monitoring.

The company's mesh technology eradicates the problems associated with off-the-shelf meshes from traditional sources, which can suffer from restrictions such as 'square-only' apertures, across-mesh rigidity problems and unwanted material retention. The new meshes can be custom produced with bespoke aperture shapes and sizes, relevant to the particles being measured, filtered or graded - with little or no cost premium - and with aperture tolerances from +/- 2 microns.

Furthermore, mesh thickness can be selectively increased, beyond 1:1 aspect ratios, to meet exact strength and rigidity requirements. For example, solid portions such as lateral supports can easily be incorporated into the design. Mesh can also be supplied to individually specified shapes with significant reductions in customer-side processing.