Posted to News on 27th Oct 2020, 00:00

Moog Modular Electrohydrostatic Actuation System (EAS) combines the best of two worlds

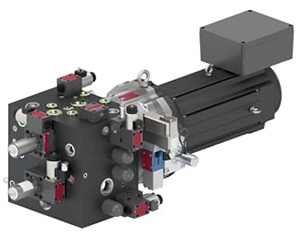

Moog Industrial Group has announced the market introduction of the new Modular EAS System – a highly flexible system with excellent scalability and variability and can be easily adapted to most types of industrial manufacturing machinery.

The Moog Modular Electrohydrostatic Actuation System (Modular EAS) features standardised modules with a wide number of customization options available. This process allows for extensive application potential by meeting the specific requirements of the customer. The system’s smallest scope of delivery consists of a basic manifold and an Electrohydrostatic Pump Unit (EPU) which Moog delivers as an assembled and tested unit.

To expand the system, the basic module can be combined with various options or adapted with additional standardised high-speed manifolds in order to build a complete motion control system. With the Modular EAS System the localized power allows for improved energy efficiency due to the elimination of the flow control valving and centralised piping, which reduces the amount of wasted energy commonly found on traditional hydraulic systems. Modular EAS benefits include:

- High force capability and force density that provide a compact and performant alternative to EH and EM actuation

- Environmentally clean due to up to 90% lower oil requirement compared to the standard systems and low noise emission for quiet machine operation

- Small number of components to reduce the risk of breakdown and allow for faster maintenance

- Decentralised system that eliminates the need for a large Hydraulic Power Unit (HPU) and reduces piping

- 4-quadrant operation technology allows for universal suitability for a large range of challenging applications as well as for effective energy management with reduced consumption due to energy recuperation

- Low mass inertia of the EPU provides high system dynamics

The Modular EAS System is suitable for a wide range of industrial manufacturing machinery. It can be used on metal pressing applications from forging, powder and sheet metal presses to hot forming, punching and isostatic press machines. In wood and paper milling, testing and power generation applications the Modular EAS System allows for improved decentralisation of the machine axes. Additional high-performance applications can be realised in the industrial marine sector, on operational mobile machinery and on injection and blow moulding machinery in the plastics sector. The system simultaneously reduces oil requirements for HPU by 90%, thereby reducing machine cost of ownership significantly.