Posted to News on 19th Sep 2014, 00:00

Magnomatics joins consortium developing aerospace actuators

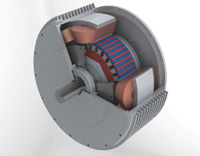

Magnomatics is proud to be part of a consortium developing new actuators for primary aircraft control systems, based upon its Pseudo Direct Drive (PDD) electric machine. The consortium is led by Triumph Actuation Systems and also includes Romax Technology and the University of Sheffield.

>The project has been funded through an open competition run by the Technology Strategy Board on behalf of the Aerospace Technology Institute. £19 million of public funding was provided with a further £11 million from industry to support new projects covering a broad spectrum of aerospace technology research. Announcing the project, Deputy Prime Minister Nick Clegg said: "The UK's aerospace industry is going from strength to strength and helping our economic recovery. We are the number one aerospace industry in Europe and second only to the United States globally.

>"I want to ensure the UK remains at the cutting edge of aerospace innovation, which is why I am pleased to announce that we are investing £154 million for research to explore new technologies like the 3D printing of plane parts and creating lighter, greener aircraft. By working in partnership with business, we are building a stronger, more balanced economy, creating more jobs and sharing the wealth equally."

>Chris Kirby, CEO of Magnomatics, said: "We are delighted to be awarded this funding which will enable us to further develop our novel light-weight and fault tolerant actuator motors. Modern aircraft are replacing hydraulic systems where possible and Magnomatics' advanced technology is able to deliver the demanding characteristics required for safety critical actuation of flight surfaces."

>The Electro-Mechanical-Magnetic Actuator Systems (EMMAS) project aims to create safer, quieter, more-reliable electro-mechanical actuator designs, containing electronics suitable for extreme environments (wide temperature ranges, and high vibration). These actuators will be vibration resilient, have capacity to thermally regulate, require less maintenance, and be resistant to 'jamming' when permanently or temporarily overloaded.

>All aspects of the actuator design process will be evaluated throughout the program. The main program topics include the development of control strategies and drive electronics, investigation of using novel magnetic gearing technology to replace a conventional motor and gear train, and full system analysis of electro-mechanical performance. The objective of the project is to advance technology capability within electro-mechanical actuation, with a key focus on increasing reliability, safety and passenger experience.