Posted to News on 7th Nov 2006, 00:00

Hydraulic sealing systems compared

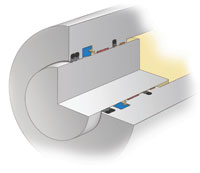

Cycle times are an efficiency factor for injection moulding machines. This explains why the cylinders that open and close injection moulding machines are subjected to such stress. Leakages in these hydraulic systems are totally unacceptable. Ferromatik Milacron, a renowned manufacturer of injection moulding machines, equipped one of its high-performance injection moulding machines (a K-Tec) with two different hydraulic sealing systems (each from a leading supplier of seals) with a view to comparing the two systems directly. In order to ensure that the sealing systems were subjected to exactly the same loads, one of the machine's driving cylinders was equipped with the sealing system from one manufacturer, and the other driving cylinder with the sealing system supplied by the second manufacturer. The leakage oil from each cylinder was collected separately.

After 139 operating hours (101,000 cycles), one of the cylinders showed first signs of leakage. After 665 operating hours (470,500 cycles), one litre of leakage oil had been collected at this cylinder. After approximately 1,150 operating hours (800,000 cycles) the volume of collected leakage oil at this cylinder had risen to an unacceptable 3 litres. The sealing system that was used on the other cylinder and was subjected to exactly the same load was supplied by Merkel Freudenberg Fluidtechnic. By this stage of the test, it had not leaked a single drop of oil.