Posted to News on 31st Oct 2022, 12:30

Gripper technology leads the charge in the transition to electromobility

Having supplied end-of-arm tooling (EAOT) for automotive powertrain manufacturing and assembly for over 30 years, Zimmer Group is now at the forefront of the technological transition to electromobility, including the pro-active development of a number of modular solutions for EV vehicle manufacturing.

As the transition away from vehicles powered by internal combustion engines to the new generation of EV’s and Hybrids continues to gather pace, OEMs are not only investing in their new pollution free models, but the manufacturing systems and technologies required to meet the growing demand from consumers.

It is not just the motive power of these vehicles which is different, the production of electric vehicles requires a complete re-think of the technologies used to manufacture their powertrain components. With batteries, electric motors, controllers, cables, and connectors replacing the conventional ICE mechanical parts, new manufacturing methods and systems are being developed to achieve the production efficiencies, economies of scale, and quality levels for which the automotive sector has become recognised.

Producing battery cells and modules economically is an important factor in ensuring that this market can continue to grow at the pace required. As for internal combustion engines, high levels of automation will be essential. Zimmer Group has been able to leverage from its extensive knowledge of powertrain assembly systems and is now applying this expertise, working in partnership with a number of premium businesses across battery manufacturing, module assembly, and electric motor production.

Richard Mason, managing director of Zimmer Group UK, explains: “Zimmer Group started developing EOAT solutions for electromobility applications as far back as 2014, and has since invested a significant number of engineering hours and R&D budget in developing and perfecting systems for this growing market segment. As a result, today, Zimmer Group’s technologies are now used by all of the leading automotive manufacturers in the EV sector. We are very proud of that achievement.”

Battery cells, modules and more

Energy storage systems for EVs generally have a modular design and consist of single battery cells that are joined into modules which are then grouped to form battery packs. The commonly used Li-ion battery has 3 different cell types which are either: small solid cylindrical cells, larger soft pouch or polymer cells, and larger solid prismatic structure types. At each stage of the manufacturing process, these cells need to be handled, grouped, and transferred efficiently and securely.

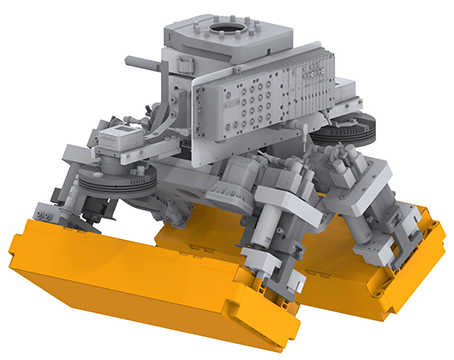

Individual cylindrical cells are handled in multiples and arranged into modules, which in turn are assembled to produce completed battery packs. Zimmer Group has developed a comprehensive range of EOAT / Gripper technologies to handle the different battery cell types through the various assembly stages. In addition, the company has gripper technologies to handle the frames, baseplates and intermediate layer and cooling plates used in the construction of the final battery packs.

Today Zimmer’s EOAT and gripper solutions are a key part of some 40 high profile electromobility projects, totalling 400 grippers and 2,000 devices, covering all aspects of the EV powertrain.

The Zimmer Group is therefore now an established and valued partner to a growing number of premium automotive manufacturers and integrators of production lines, providing handling systems and fixtures for the production of battery cells, battery packs and battery modules. The company also supplies specific system solutions for rotors, stators, contact rings, gears, and various added value parts along the EV supply chain.