Posted to News on 21st Mar 2019, 00:00

Getting a grip in the automotive industry

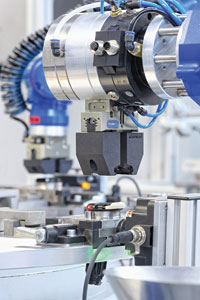

Additively manufactured gripper fingers have opened up new possibilities for a supplier of robotic handling systems within the automotive industry, with reduced design time, increased speed of delivery of the grippers and a lower item price.

With around 300 employees, German company ROS develops and manufactures highly precise tools and plants at its Coburg and Ummerstadt plants for the production of functional and visible parts for the automotive industry. For example, ROS provides a comprehensive portfolio of components for headrests and seat adjustments. Worldwide, in virtually all cars in the premium segment, guide bushings are fitted by ROS to lock the headrests.

ROS is extremely open to innovative technologies, and has begun to reap the benefits of a new service from Schunk: the gripper specialist now provides an online tool where companies such as ROS can upload the gripper step or STL data, or configure the required gripper finger by means of a few specifications with regards to material, gripper type, installation position and finger length. Once the order is confirmed, the required grippers are additively manufactured.

In two assembly plants for a Bavarian car maker, ROS has fully used the potential of the 3D design tool for the first time. Within two weeks, the additively manufactured gripper fingers were delivered to ROS – additively manufactured, with the contour precisely specified by the company.

Comparing the new service with a more traditional way of working, Christopher Lamprecht, production planner at ROS, says: “All in all, the online tool has saved a great deal of work in device construction. From developing the idea, to the first tests, milling operations and coordination, two days would certainly have been needed before. But with eGRIP, the effort was half an hour max.”

When the fingers were delivered, they worked straight away: “You mount the jaws, teach in your point, close them and that’s it. Awesome,” adds Lamprecht. The impact of this online shop for individually designed gripper fingers is impressive. According to Schunk’s estimates, it enables the design time for gripper fingers to be reduced by up to 97%. The production and delivery time is reduced by up to 88%. In addition, the finger price is reduced by up to 50%.

Eight to ten different sleeve variants can be produced for each machine today: for this, the guide bushings are separated on one linear unit and delivered suspended. A camera records the rotational position and transfers the values to the robot, which grips and places the sleeve precisely aligned on the rotary table using a multi-tooth guided Schunk universal gripper PGN-plus 64. At each station, springs, buttons and caps are then assembled. A second robot, which is also fitted with a Schunk PGN-plus gripper, serves to discharge NIO parts. For this, secure access must be ensured, regardless of which components were fitted before and which ones were not. The gripper jaws of the two Yaskawa robots used differed accordingly.

So that the material of the gripper fingers can be precisely adjusted for the specific application, there are three materials on offer from Schunk eGRIP: stainless steel fingers with a material density of g/cm3, a tensile strength of 700N/mm2, an elasticity modulus of 190kN/mm2, an elongation at fracture of 34%, and a tolerance of ±0.1mm (coating thickness 30µm) or ±0.2mm (coating thickness 50 µm) are primarily suitable for sophisticated applications in machine manufacturing. Fingers made of aluminium (AlSi10Mg) or polyamide 12 however show their strengths primarily in dynamic assembly applications. The latter, with a density of barely 0.9g/cm3, are extremely lightweight, resistant to chemicals, suitable for use with food products and can also be used reliably in connection with cooling lubricants and aggressive media.

Schunk also offers top jaws made of FDA-approved polyamide 12 (PA 2201) specially for use in the pharmaceutical and medical sector. For Lamprecht, the polyamide fingers also offer additional benefits: “While until now usually conventionally manufactured aluminium fingers had been used, we chose polyamide for the additively produced fingers. This will ensure that the sleeves are handled carefully.” With respect to the durability, Lampert is confident: “Up until now, the plastic fingers only exhibit minimal wear, which is very good news.” Looking forwards, he sees excellent implementation possibilities for the 3D printing fingers: “When we have to tightly grip difficult parts in the future, we will certainly use eGRIP again."

Schunk has provided the order process with all sorts of options. If you don't want to order the gripper fingers immediately, you can recall the automatically saved offer later using the configuration number, continue processing it or request it via email so as to submit it to the purchasing department later. The external contour of the generated modules, consisting of gripper, top jaws, and workpiece, can also be downloaded free of charge as an STL file and used directly for the construction of the system.

Follow-up orders are just as easy, because all orders can be recalled again, activated again or adjusted at any time. The intelligent web tool, for which there is a user guidance in German and English, is available for the Schunk PGN-plus universal gripper 40 to 125 (polyamide) or PGN-plus 40 to 80 (aluminium and stainless steel), for the pneumatically controlled Schunk MPG-plus 20 to 64 small-components grippers, and for the electrically controlled 24V Schunk EGP 20 to 50 small-components grippers. Orders can also be placed from EU countries and Switzerland.