Posted to News on 6th May 2025, 12:00

Drive solutions for the baking and confectionery industry

At iba 2025 in Dusseldorf (18 to 22 May), NORD DRIVESYSTEMS will be presenting drive solutions for hygienically sensitive applications in the baking and confectionery industry. The focus will also be on the NXD tupH procedure developed by NORD for the treatment of aluminium surfaces.

NXD tupH surface treatment for aluminium

With its NXD tupH surface treatment, NORD makes the surfaces of drives with aluminium housings particularly corrosion-resistant. Aluminium is lightweight, economical and fully recyclable.

Furthermore, aluminium housings provide better heat conductivity than, for example, stainless steel, thus reducing their maximum surface temperature. The NXD tupH coating consists of a base layer, which transforms the top layer of the aluminium body into a corrosion-resistant layer.

The combination with a sealer achieves extreme resistance with better hardness compared to an untreated aluminium alloy. This treatment prevents flaking or corrosive infiltration, meaning that the protective effect remains intact even in the event of minor mechanical damage.

The surfaces of drives finished with NXD tupH are largely resistant to acids and alkalis and can be cleaned easily, thoroughly and hygienically. The surface finish therefore offers major advantages when used in hygiene-critical areas in the food, beverage, packaging, pharmaceutical or chemical industry. NXD tupH surfaces are free from PFAS, and food-safe according to the FDA, the EU Regulation 1935/2004 and the respective regulations in Switzerland and the MERCOSUR states.

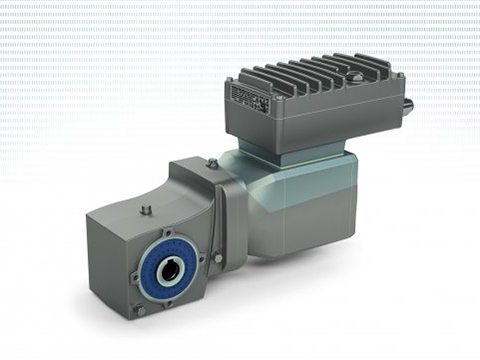

Smooth IE5+ synchronous motors

With its smooth and fanless IE5+ synchronous motors (TENV), NORD offers efficient drives for use in the food and beverage industry as well as the intralogistics sector. Users are provided with models up to a power of 2.2 kW, with a continuous torque from 1.6 to 10.0 Nm, and speeds of up to 2,100 min-1. Thanks to the hygiene-friendly, smooth design, the housing is particularly easy to clean.

With the optional food-compliant NXD tupH surface finish, the drive housings are also corrosion-resistant and wash-down capable, making them ideal for reliable use in hygiene-sensitive environments. The IP69K protection class is another option. Further excellent features of the IE5+ synchronous motors (TENV) include the constant high efficiency over the entire adjustment range and the flexible motor mounting (direct mounting, NEMA, IEC).

SAFOMI-IEC adapter for agitators

The compact SAFOMI-IEC adapter (SAFOMI = Sealless Adapter For Mixers) is simple in design and was specially developed by NORD DRIVESYSTEMS for mixers and agitators. It is equipped with an integrated oil expansion chamber and, in combination with the MAXXDRIVE industrial gear units, offers decisive advantages such as increased reliability and reduced maintenance. The integrated oil expansion chamber makes oil hoses or the radial shaft seal that is prone to leakage and wear superfluous.

SAFOMI is available for MAXXDRIVE parallel gear units in sizes 7 to 11, or for maximum output torques from 25 to 75 kNm. The combination of the MAXXDRIVE industrial gear unit, SAFOMI-IEC adapter and a drive motor is a compact alternative for mixers and agitator applications in order to reduce wearing parts and attached components.