Posted to News on 30th Mar 2017, 00:00

Drive component efficiency and their impact on the system

When considering motor driven applications with limited power supply – such as a battery driven tool or a solar panel powered satellite – it is natural to try to source the motor with the highest efficiency. But it is worth expanding the consideration to the complete drive system, looking not just at the motor but also at the controller, gearhead and other mechanical components.

In particular, looking at the efficiencies of the mechanical systems, a lot depends on how those systems are made. High friction in the mechanical system costs a lot of energy. Hence optimising the efficiency of a drive train should always start with the mechanical system.

DC drive systems are very often powered by a fixed voltage so it is not really the overall efficiency that must be maximised. Efficiency is a relative parameter giving the losses per input power. However, at fixed voltage it is rather the current consumption (as an absolute parameter) that needs to be minimised. Making good use of the full supply voltage reduces the current consumption – and lengthens battery life. So here are a few rules for ensuring high efficiency and low current consumption.

Rules for mechanical transformation

- Use low friction mechanics or avoid it all together.

- Use rolling friction (coefficient of friction < 0.01) instead of gliding friction (typical friction coefficients 0.1 … 0.4). For example, a ball screw system has a considerably lower friction than a lead screw. However, a ball screw solution is usually not self-locking; it needs to be powered to remain at a stop position. Considering the full working cycle, there are situations where an acme screw might consume less energy in total.

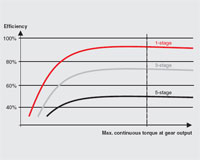

Rules for planetary and spur gearheads

- Use a low number of stages.

- Use small gearheads with torque ratings only slightly higher than what you need. Don’t oversize the gearhead. Efficiency at low gearhead load is very bad.

- In terms of efficiency, a larger direct drive motor without gearhead is often better than a motor-gearhead combination. However, the direct drive might be larger, heavier and more expensive.

Rules for motors

- Run the motors at speeds of several thousand rpm.

- Don’t select too large a motor. Don’t run it close to no-load.

- Take care when selecting the winding. Use one that makes the best use of the voltage to reach the speed under load; that’s the one that needs the lowest current.

Rules for controllers

Here the rule is similar to gearheads. Load them well, don’t run them at too low a current. Don’t select controllers with too high a current rating. Match the size of the power stage with the required motor current.

Last but not least, make good use of the full supply voltage. This reduces the current consumption and you can save money; you will need a smaller power supply, a smaller controller, less cable shielding. As one engineer put it: voltage is free – current costs.