Posted to News on 5th Jun 2025, 12:00

DrillOptimizer from Aerotech reduces cycle times for galvo scanners

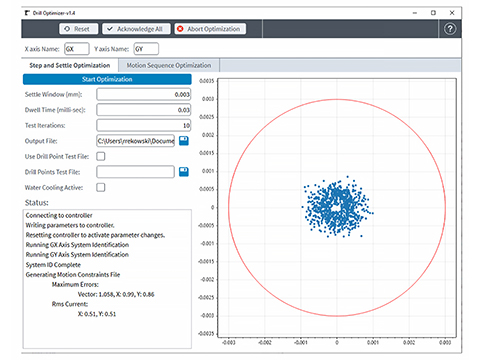

With DrillOptimizer, Aerotech is expanding its Automation1-iSMC control solution with a powerful feature for highly dynamic laser drilling with galvo scanners. The programme, which has been specially developed for drilling large quantities of vias, noticeably reduces cycle times when drilling several million holes - while at the same time ensuring consistently high processing quality.

DrillOptimizer is part of the AeroScriptPlus library and is available both as a user-friendly interface in Automation1 Studio and as a .NET DLL, which enables seamless integration into existing machine HMIs.

"The optimisation of point-to-point movements for complex drilling patterns has long been a bottleneck. DrillOptimizer automates these steps, reduces process time and ensures maximum precision," explains Bryan Germann, Product Manager at Aerotech.

Intelligent motion logic for demanding drilling applications

DrillOptimizer is part of the AeroScriptPlus functionality and uses a two-stage optimisation approach that takes into account both path planning and movement parameters:

Optimisation of motion sequences: DrillOptimizer calculates the shortest path through the entire drilling pattern - within a single field of view (FOV) or in combination with a servo table system for an infinite field of view (IFOV). This saves travel time and increases the overall throughput.

Optimisation of steps and settling: Individually suitable control parameters are determined for each specific step distance - without the galvo scanner leaving the predefined settling window. As soon as the scanner is in the so-called settling window, the laser can be triggered without delay. This eliminates unnecessary downtimes between drillings.

Partner for demanding laser processes

DrillOptimizer is aimed at equipment manufacturers who realise laser drilling processes with maximum efficiency and precision - for example in PCB production, micro material processing or semiconductor technology.