Posted to News on 26th Feb 2025, 14:00

Digital strain wave gears without additional space requirement

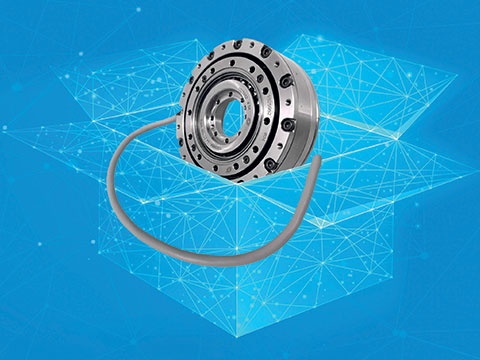

New from Nabtesco Precision Europe is a digital strain wave gearbox without additional space requirement. The company says these zero backlash plug and play solutions open new potentials in performance, condition monitoring, process optimisation, cost efficiency and machine and robot availability, thus introducing a new era.

The new strain wave gear integrates smart sensors with the same dimensions as a standard gearbox to create an extremely compact solution for smart automation. Said to be unique on the market, this concept offers numerous advantages.

Sensors measure torques, temperatures, and vibrations. In combination with practical empirical values, they provide reliable information on the condition of the gearbox. The integrated electronic evaluation unit (EEU) analyses the data and sends it directly via the bus system to the higher-level controller. The operator receives recommendations for action, in order to respond promptly to changing parameters and to initiate appropriate measures.

Continuous condition monitoring makes it possible to calculate the actual life of the gearbox, to determine gear faults, to identify overloads, unsuitable operating points and misuse cases, and creates the conditions for optimisation strategies and predictive maintenance. All in all, the potential savings are in the double-digit percentage range.

"Our compact, sensor-based strain wave gears expand our spectrum of digital solutions and take drive technology into the future. Our plug-and-play product combines high-precision, zero backlash technology with smart sensors and artificial intelligence - with no change in the size of the gear. This solves central problems faced by our customers and is a major factor in boosting efficiency, optimising performance, saving resources, and improving cost-effectiveness," says Daniel Obladen, Director Sales and Marketing at Nabtesco Precision Europe, describing the advantages in a nutshell.

The digital strain wave gears are produced at the Ovalo location in Limburg/Lahn in compliance with automotive standards (IATF certification 16949). They feature absolute zero backlash, outstanding repeatability, a maintenance-free design, 100% traceability, and a high torque capacity (up to 15% higher compared to conventional strain wave gears) - all in a compact and lightweight design.

They can also be customised for the particular application in terms of performance, geometry, material, and interfaces, including functional, component and system integration, as required.

The digital strain wave gear is available as a gear set plus, gear unit, hat type gear (HTG), cup type gear (CTG), and with or without a hollow shaft. The gears are calibrated in Limburg/Lahn, eliminating the need for calibration in the target application by the customer.