Posted to News on 16th Apr 2025, 11:00

Contrinex launches smart double-sheet detection sensors

Contrinex says it has set a new standard for Double-Sheet Detection Sensors, delivering precision, durability, and ease of use. Double-Sheet Detection Sensors aim to eliminate costly tool damage in press lines by ensuring that only single-sheet blanks are fed to the presses.

Contrinex's robust Smart Inductive sensors were soon introduced to the challenges of double-sheet detection on press lines. At the end of 2023, the CBM's Metal Matters magazine carried an article describing their use by a press tool engineer to create a low-cost and adaptable double-sheet detection system.

In response to customers' requests, Contrinex has simplified things by launching dedicated Double-Sheet Detection Sensors and a specialised configuration app. The setup is now straightforward, and it takes less than 90 seconds to follow the app prompts on a phone or tablet. For example, setup can now be done within the remit of a setter/operator rather than needing the deeper knowledge of a maintenance engineer.

The SMART Double-Sheet Detection Sensors are robust, with the sensor's front face and sides being machined from a single piece of V2A (AISI 304) stainless steel. To further protect the sensors from damage, they can detect sheet materials between 3 and 5 mm away. Providing a contactless solution extends sensor life and can also provide advantages in reducing potential contamination.

Available as either M18 or M30, the sensors can detect steel, aluminium or stainless steel sheets. Material thickness can vary from a minimum of 0.2mm to a maximum of 4mm for aluminium or a range of 0.5 to 2mm for steel, for example.

Fast configuration using the hand-held PocketCodr communication module and a phone or tablet enables the sensors to work with multiple materials and sheet thicknesses. Contrinex's SMART Double-Sheet Detection Sensors offer a flexible and easy-to-use solution at a much lower cost than other systems, perhaps enabling double-sheet detection to be applied where it was not previously affordable.

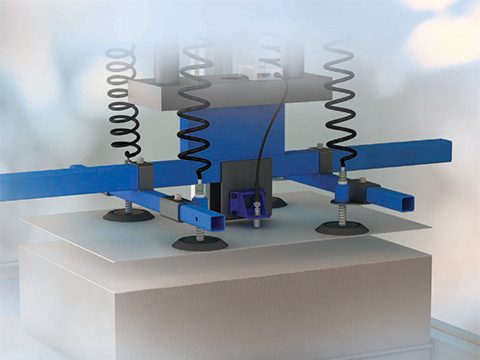

A typical application would see a Smart Double-Sheet Detection Sensor integrated into the blank sheet material vacuum picker, looking down 'through' the metal blank to ensure that there isn't a second sheet below it.

Suppose the sensor detects the presence of a second sheet, perhaps attached due to the stickiness of the protective oil coating; the press line operation will be suspended, and an alarm is triggered before damage can occur.

Configuring the sensor is fast and straightforward, requiring a guided set of intuitive selections on the PocketCodr app. The sensor's status is clearly shown, as per the above screenshots, where the first output switching signal (OSS1) indicates the presence of the sheet material, and the second (OSS2) shows the presence of a second sheet. Once configured, the sensor is reconnected to the machine's control system, and production can begin.

Robust and reliable detection is assured with features such as a short delay being built-in before triggering the output to prevent false positives from occurring in the event of a momentary change in either of the internal signals.