Posted to News on 6th Jun 2024, 14:00

Cambridge Vacuum Engineering shortlisted for national engineering award

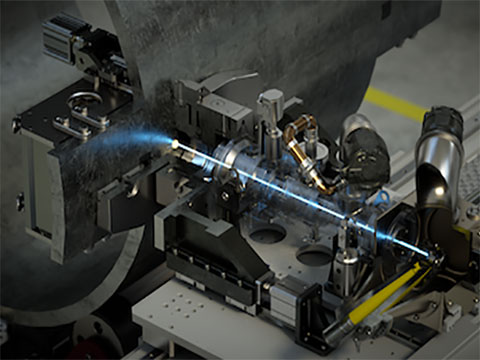

Cambridge Vacuum Engineering (CVE) - a specialist in power beam welding technologies - has been shortlisted for a prestigious Engineering and Manufacturing Award for its Ebflow technology, which is fast emerging as a key enabler in the transition towards a net-zero future.

Showcasing the very best that UK engineering has to offer, the Engineering and Manufacturing Awards celebrate game-changing and disruptive technologies within the sector.

CVE is shortlisted in the 'Manufacturing Technology Innovation' category for its Ebflow technique. This category recognises innovative manufacturing techniques that are having a tangible impact across industry. CVE's Ebflow technology, which is currently making waves across the energy sector and helping to speed up construction of key infrastructure components such as wind turbines and small modular nuclear reactors, clearly impressed the judges with its capabilities.

Bob Nicolson, Managing Director at Cambridge Vacuum Engineering, said: "Being shortlisted for this national award is testament to the ground-breaking nature of our Ebflow technology and the outstanding results it is delivering. Faster, leaner, and cleaner, Ebflow can help accelerate manufacturing across an array of applications, and in the case of the energy industry, could be the key to speeding up the drive toward a new era of sustainable energy production. We eagerly anticipate the outcome of the awards ceremony in September."

Ebflow was recently used to fast track the production of a monopile foundation for an offshore wind turbine for Dogger Bank, the world's largest offshore wind farm. The monopile transition piece, created using Ebflow, was part of RapidWeld - a ground-breaking project funded by Innovate UK and led by a consortium including SSE Renewables, CVE, DNV, Sif Netherlands, Agile NDT and The Welding Institute (TWI). The RapidWeld project team achieved welding speeds at least 25 times faster than the current default manufacturing method. Production required 90% less energy, cost 88% less, and produced 97% less CO2 emissions.

Ebflow also recently helped Sheffield Forgemasters cut the amount of time needed to weld a small modular reactor (SMR) pressure vessel demonstrator from more than a year, to less than 24 hours - a move that could help reshape the future of nuclear reactor production worldwide and bridge the gap in the UK's energy market.