Posted to News on 17th Feb 2017, 00:00

Autodesk highlights 2017 FeatureCAM and PowerMill CAM at Southern Manufacturing

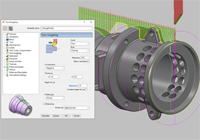

Autodesk is showing its new 2017 CAM products for a multitude of advanced manufacturing applications ranging from CNC mill and lathe programming to complex mould and die manufacturing. These new products combine the heritage of industry leadership in CAM software from Delcam with Autodesk’s 3D design and manufacturing prowess, presenting Autodesk CAM customers with a powerful and unique user experience.

On stand Q103 at Southern Manufacturing, Farnborough from 21st – 23rd February, Autodesk will be exhibiting the 2017 releases of Autodesk FeatureCAM for automated CNC programming and Autodesk PowerMill for high-speed and multi-axis machining.

PowerMill 2017 takes the ability to easily and effectively manufacture the most complex moulds, dies and other components to new heights. This latest version includes the following new features:

- More efficient 3D offset finishing toolpaths, greater simulation controls and constraint-based logic to optimize non-cutting link moves for safer, more efficient machining

- For the first time, PowerMill also provides strategies to create turning routines for use on 5-axis mill-turn machines

These improvements continue to make PowerMill the ideal choice for manufacturers looking to solve the most demanding of 3-axis, high-speed and complex multi-axis applications.

FeatureCAM is for automating CNC programming of milling machines, turning and turn/mill centres, Swiss lathes and wire electrical discharge machines (EDMs). The automation tools within FeatureCAM help manufacturers reduce programming time, allowing parts to be made faster. They also increase programming consistency for maintaining part quality. The 2017 version of the product includes the following improvements:

- New programming capabilities for dual-path Swiss-type lathes, further improving its range of CNC machine support

- Ability to import and view product and manufacturing information directly from a model in order to help visualize design specifications

- Access to functionality that allows pre-drilling when using Vortex toolpaths, ruling out the need for helical ramp moves.