Posted to News on 28th Jun 2024, 13:00

KABELSCHLEPP Metool presents second sustainability report

KABELSCHLEPP Metool has updated its sustainability report. The cable carrier manufacturer presents a comprehensive analysis of its sustainability efforts in terms of environmental protection, economics, and social responsibility and defines the course for future climate-neutral corporate governance.

"The report demonstrates to our customers, employees and the regions where we work what we have done in terms of sustainability and what we are planning for the future," explains Frank Springer, Sustainability Officer at TSUBAKI KABELSCHLEPP. "It is a transparent analysis of what has been achieved and also an open assessment of our position."

KABELSCHLEPP Metool has been increasingly focusing on sustainability for four years. The main drivers are the company's own motivation to contribute to climate protection along with its affiliation with the Japanese parent group TSUBAKIMOTO Chain, who is pursuing the SBTi (Science Based Targets Initiative) targets and has the ambition to be among the top 500 companies worldwide in terms of sustainability.

For the entire TSUBAKI Group, this results in ambitious requirements and further tightening of the sustainability targets. The CO2 savings specified for 2023 were increased and the reference year for these values was changed from 2018 to 2021.

To overcome these challenges, KABELSCHLEPP Metool has tightened the already defined and prioritised fields of action. After achieving a reduction of the CO2 emissions of 27.6 % in scope 1 and 100 % in scope 2 at the end of 2023, the company now also wants to use the appropriate measures to unlock even hard-to-achieve savings potentials. To do this, it has a number of different sustainability projects in the pipeline, for which an investment volume of 500,000 to 600,000 euros is planned for 2024 alone.

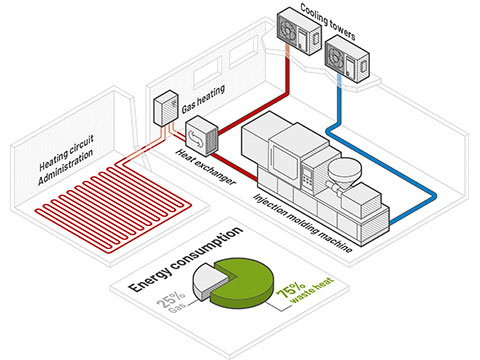

In 2023, the catalogue of measures included load peak management in production, preparation for DIN EN 14001 certification, planning of a 3,200 m2 photovoltaic system, and preparation of new heating systems at the Wenden site. KABELSCHLEPP Metool has already been heating its complete administration building with waste heat from production since 2022, reducing natural gas consumption by around 75 %.

In addition to this, considerations of scope 3 logically dominated a substantial part of the documentation. The evaluation of the supply chain was a crucial part of this, with waste and vehicle management as well as a number of other topics were also being initiated.

"While we primarily focused on reducing the emissions from scopes 1 and 2 in the first years, our current step towards climate neutrality centres around scope 3," reports Frank Springer. "We already progressed quite far along this path in 2023. And, the better we know the scope-3 emissions, the closer we get to the truth of which CO2 quantities our company emits and which tasks are still ahead of us."